We are leading manufacturer, supplier, and exporter of premium shale shaker screens based in Gujarat, India. Renowned as the largest shale shaker screen producer in India, With advanced technology and premium materials, we provide durable, high-performance shaker screens for the oil & gas, drilling, and mining industries.

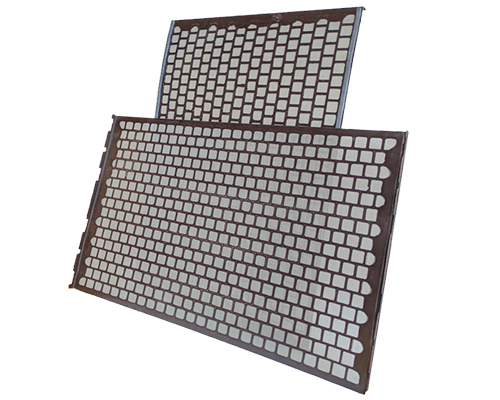

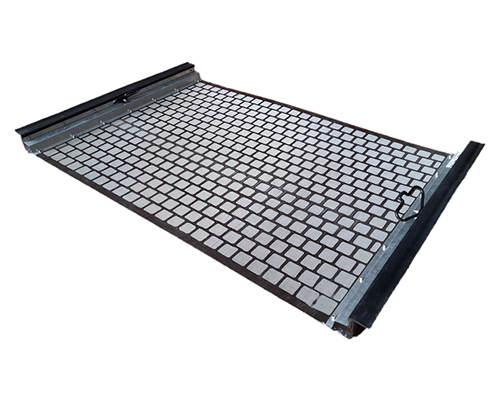

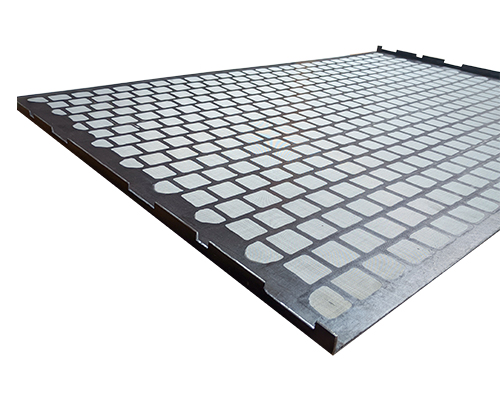

Shale shaker screens are essential filtration components used in oil & gas drilling, mining, and solid control systems to separate solids (drill cuttings, debris) from drilling fluids (mud). Installed on shale shakers, these screens help maintain mud quality, improve drilling efficiency, and protect downstream equipment. Available in various types like hook strip, flat panel, pyramid, and composite frame screens, they are designed for durability, high performance, and compatibility with major OEM brands such as Derrick, MI-Swaco, and NOV Brandt. Shale shaker screens play a crucial role in reducing waste, lowering costs, and enhancing overall drilling operations.

This process is crucial for: Maintaining drilling fluid quality, Enhancing drilling efficiency, Reducing wear and tear on equipment, Lowering operational costs

shaleshakerscreen.co.in, based in India, is a prominent manufacturer specializing in shale shaker screens and solid control equipment. With over 30 years of collective experience in the industry, established itself as the largest manufacturer of replacement shale shaker screens in India.

We offers a diverse range of shale shaker screens, including OEM replacements and custom-designed options. Their annual production capacity reaches up to 30,000 screens, showcasing their commitment to meeting market demands efficiently. The company emphasizes innovation and cost-effectiveness, ensuring that their products enhance filtration characteristics and optimize solid control efficiency.

Shale shaker screens are critical components in the oil and gas industry, specifically in drilling operations. These screens are used in shale shakers, the first stage of the solid control system, to efficiently remove drill cuttings, sand, and other solids from drilling fluids (mud). This process ensures cleaner drilling fluid, reducing equipment wear, enhancing drilling efficiency, and lowering operational costs.

In oil fields and drilling sites, high-quality shale shaker screens improve mud recycling, extend the life of drilling equipment, and ensure smooth operations. Available in various types such as hook strip, flat panel, pyramid, and composite frame screens, they are designed for high durability, better filtration, and compatibility with leading OEM shale shakers like Derrick, MI-Swaco, and NOV Brandt.